Technical Specification

Property | Units | Clay Brick | AAC Block |

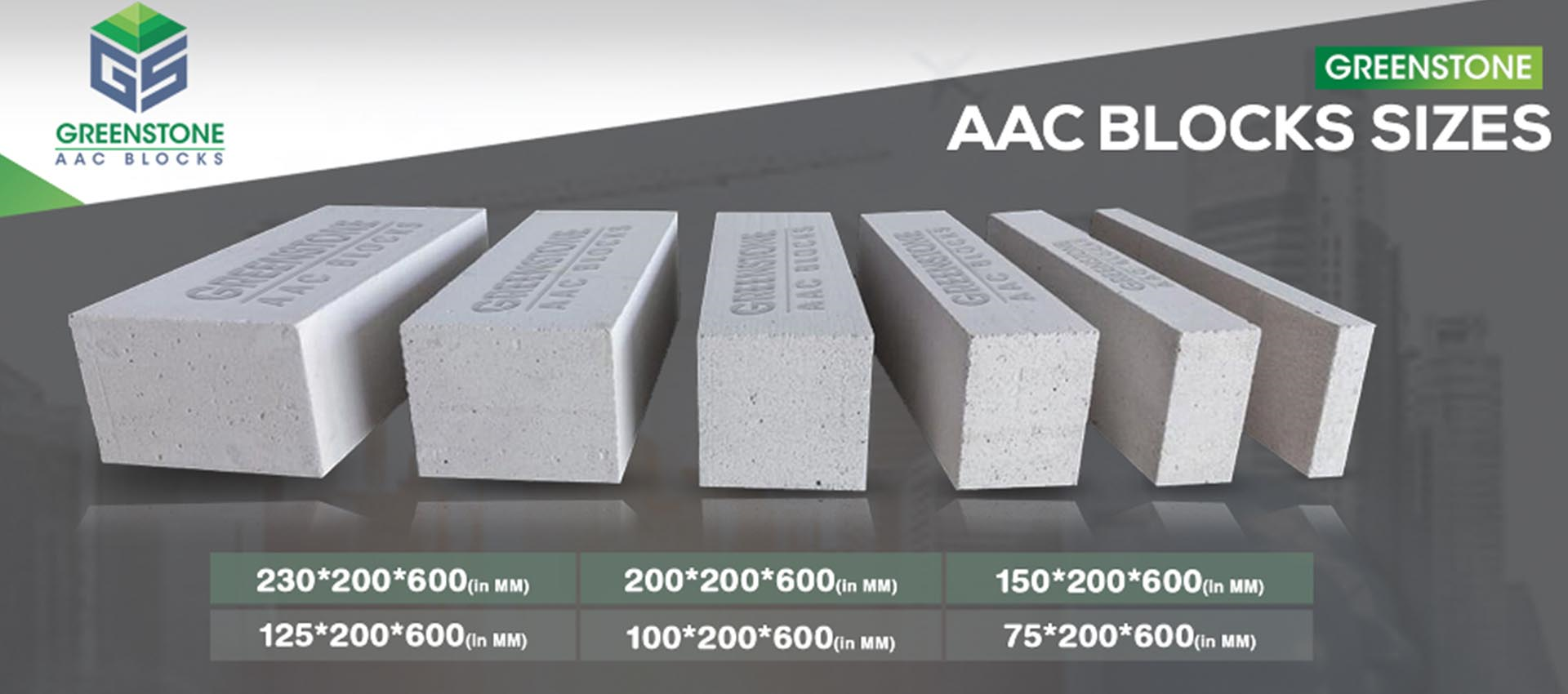

Size | mm | 230x75x115 | 600x200x(75 to 230) |

Tolerance | mm | 5-15 | 1.5 |

Strength | N/mm 2 | 2.5 – 3.5 | 3 – 4.5 (IS 2185 part3) |

Dry Density | Kg/m3 | 1800 | 550 – 650 |

Sound Reduction Index | Db | 50 for 230 mm Thick Wall | 45 for 250 mm Thick Wall |

Resistance to Fire | Hrs. | 2 | 2 to 6 |

Thermal Conductivity | W/m-k | 0.81 | 0.16 – 0.18 |

Drying Shrinkage | % | – | 0.04% |

Parameter | AAC Block | Clay Bricks |

Cost | Saving on Steel up to 15% | Zero Saving |

Cement Mortar for Plaster & Masonry | Need less due to less number of joints, flat and even surfaces | Need more because of uneven surface and excess number of joints. |

Breakage | 5% and less | On an average of 10 – 12 % |

Construction speed | Speedy construction due to its big size, lightweight & ease to cut in any size or shape | Comparatively slow |

Quality | Uniform & Consistent | Normally varies |

Fitting & Chasing | A wide variety of fitting and chasing are possible | A wide variety of fitting and chasing are possible |

Carpet Area | Required more as the thickness of walling material is less | Very low when compared to AAC |

Availability | Anytime | Shortage in monsoon |

Energy Saving | Approx. 30% reduction in air-conditioned load | No such saving |

Chemical Composition | Sand or Fly-ash will be used around 60 – 70 % which reacts with Lime & Cement to form AAC | Soil is used which contains many inorganic impurities like sulphates etc. resulting in efflorescence |